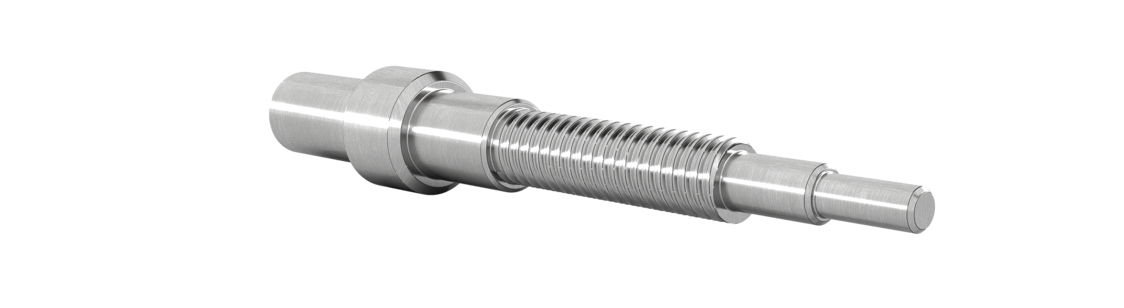

High-precision surfaces? Many can do that. But not in a fraction of the time.

Leistritz whirling machines combine the quality of grinding with the process time of milling. Thus, you produce surface quality of the highest IT class and save precious resources. But not only that: dry machining eliminates the need for coolants. The result is perfect workpieces - and additionally recyclable chips.

A Win-Win-Win-Situation!

As fast as milling

As precise as grinding

No coolant

recycable chips

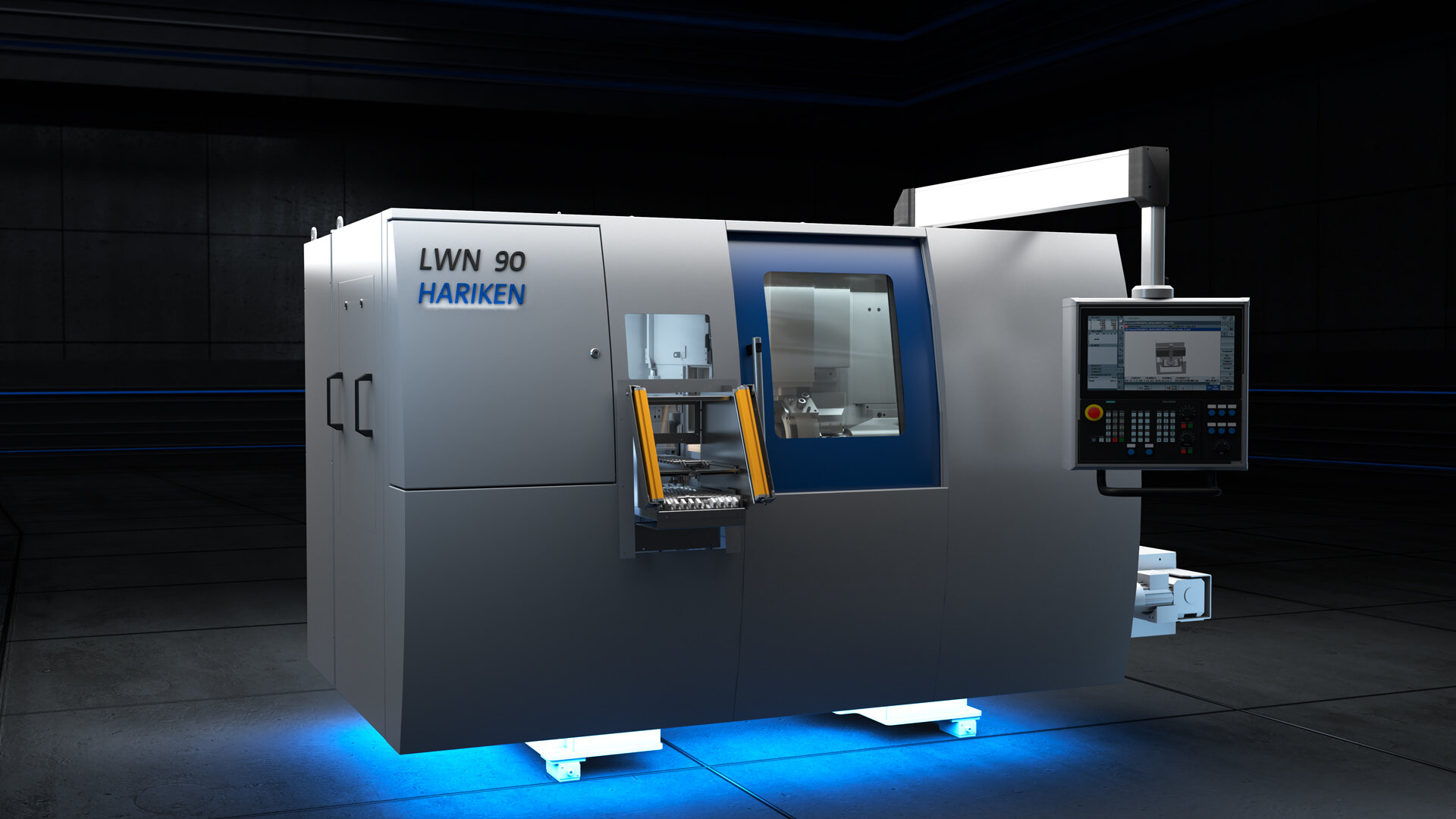

LWN 90 Hariken

The whirlwind in profile milling

Compact Design

With a size of only 1.72m x 3.2m x 2.03m you save valuable floorspace

Speed isn‘t everything - It‘s the one thing that matters

With up to 12,000 rpm you can machine workpieces in the shortest possible time - Up to 6x faster than grinding

Precision is what we do

With the LWN 90 Hariken, workpieces up to IT class 1 are possible

Precise up to the µ

Surface accuracy up to Rz 2

Operation made easy

Modern control technology makes the machine child's play to operate - for optimum process reliability

So much free space

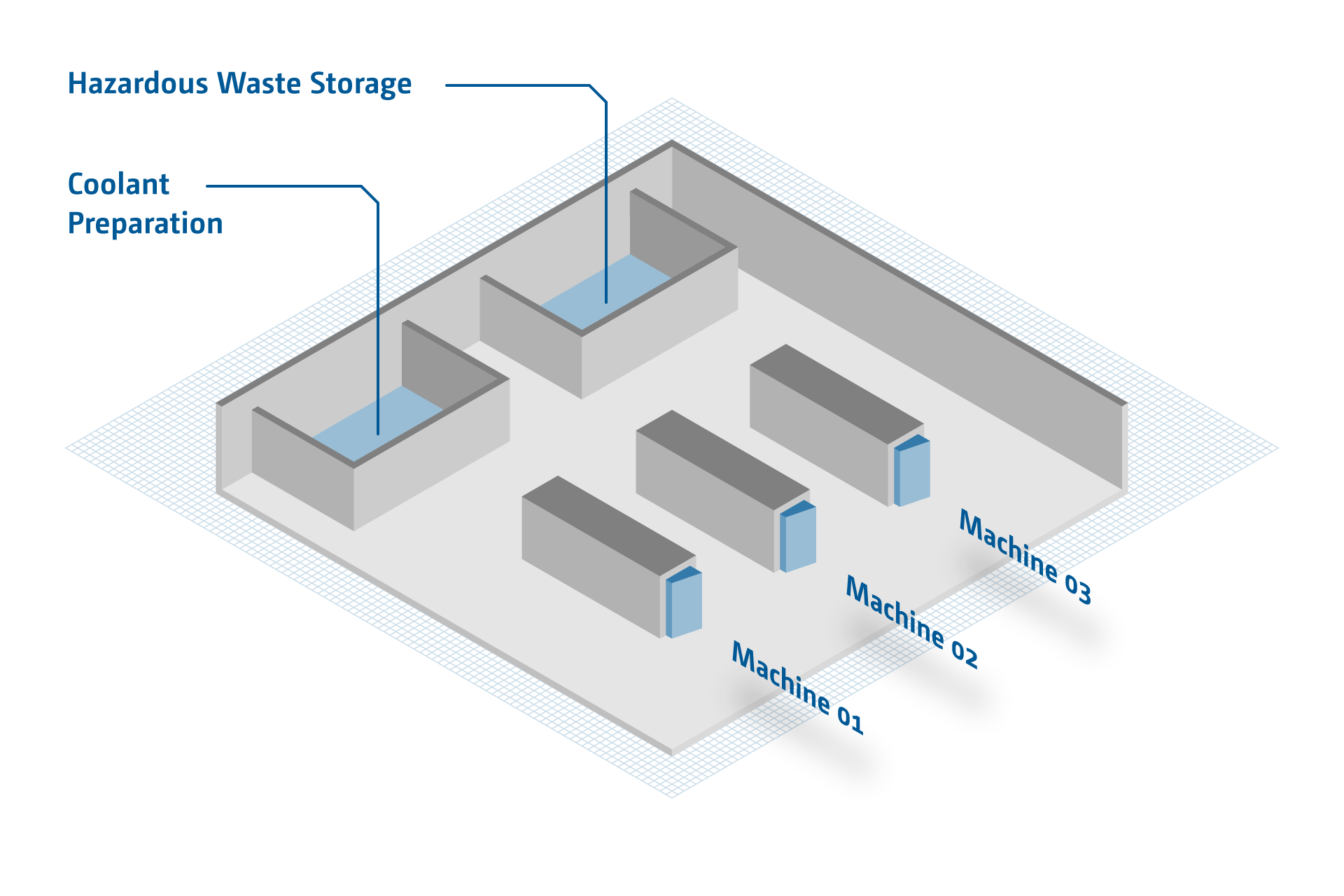

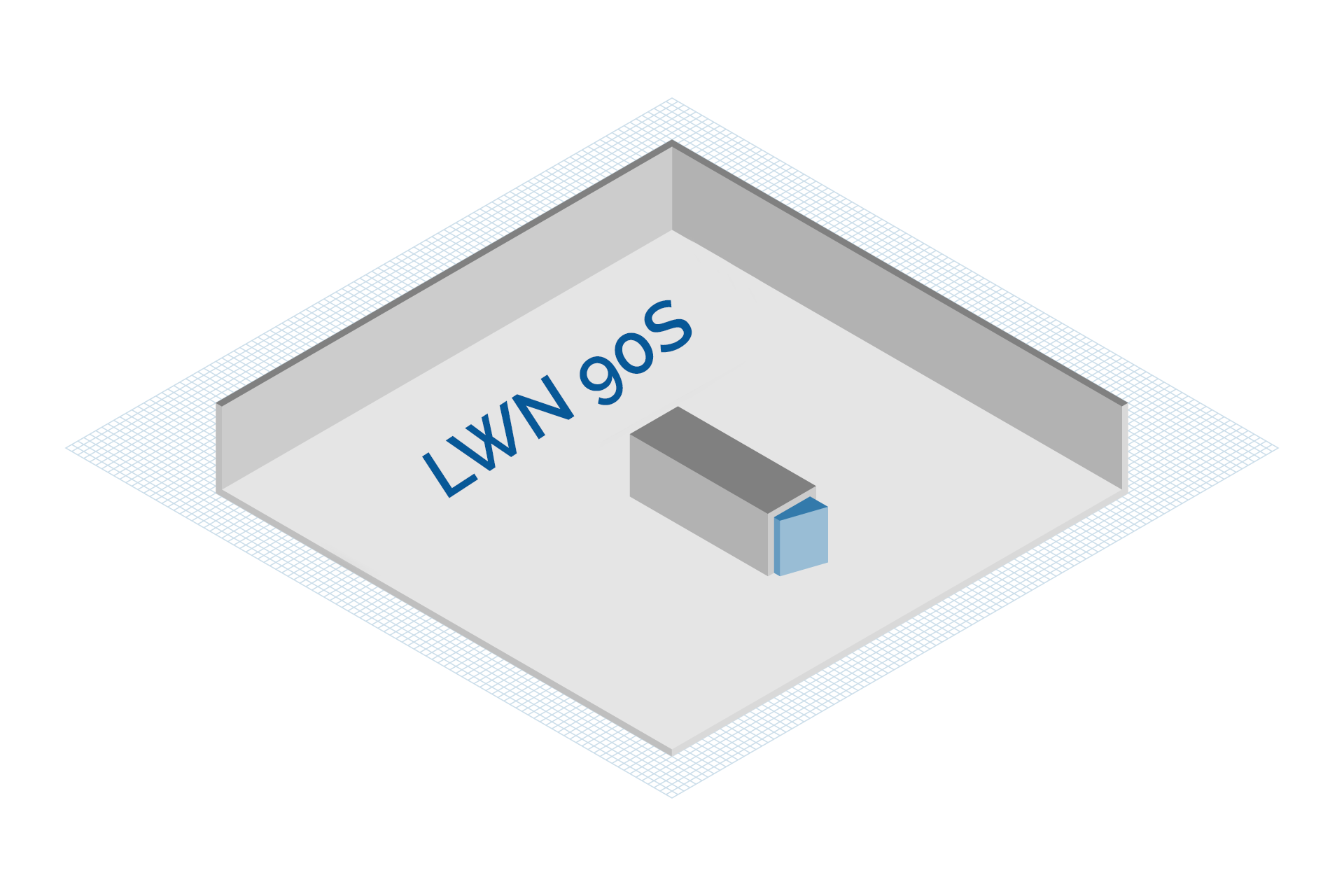

Just imagine: You would not need coolant for the machining of your workpieces and thus no coolant preparation, your chips can thus be recycled and you do not need a warehouse for the disposal of hazardous waste and instead of three machines you only need one.

Impossible?

This interactive graphic offers you a preview of your future space.

Get in touch

We tell you why the LWN 90 Hariken is the best solution for your application.

Patrick Schuka

Head of Sales Machine Tools

Leistritz Produktionstechnik GmbH